2740 Acrylic Fiberglass Sleeve

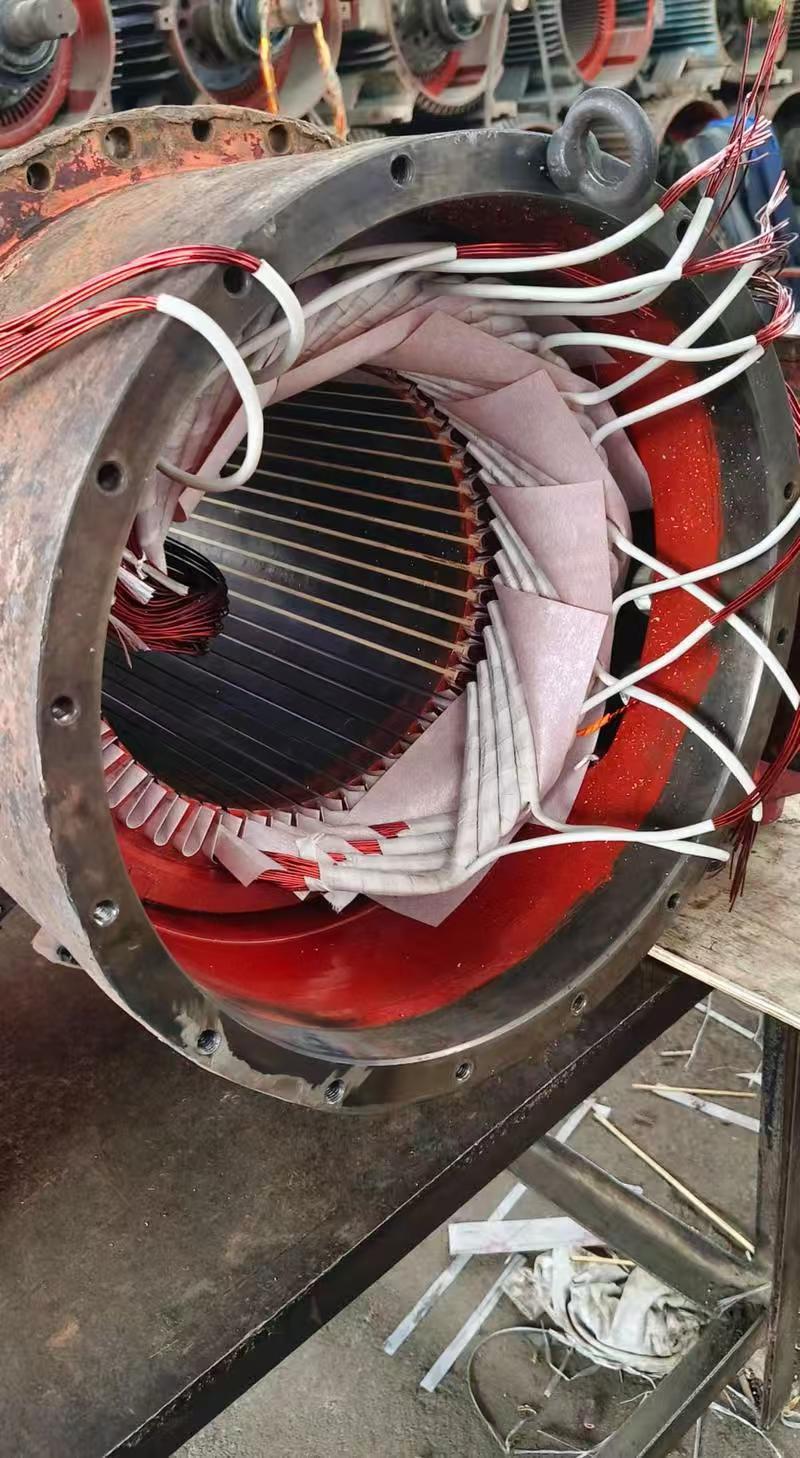

It is used in electrical apparatus such as electric motors, transformers, generators, home appliances, lighting fixtures, instrument circuits and controls, switchgear, breaker panels, welding equipment.

Categories:

Insulation sleeve

WhatsApp:+8615290922111

Email:info@hnzfe.com

Product features

1. Chemical stability:

Silicone tube usually has excellent chemical stability, can resist a variety of acids, alkalis, salt compounds and organic solvents, in addition to strong alkalis, hydrofluoric acid and a few other substances, does not react with most chemical substances. This characteristic makes 2740 silicone tube in a variety of chemical environments can maintain stable performance.

2. High temperature resistance:

Silicone tube has good high temperature resistance, can work stably for a long time under high temperature without deformation or melting. According to the different materials of silicone, its temperature resistance can range from tens of degrees below zero to hundreds of degrees. For 2740 silicone tube, although the specific temperature range is not directly given, but it can be assumed that it should have a high temperature resistance.

3. Weathering and aging resistance:

Silicone material has excellent weathering and aging resistance, can resist the erosion of ultraviolet rays, oxygen, moisture and other external factors, to maintain long-term stable performance. This makes the 2740 silicone tube maintain its original function and appearance even in outdoor or long-term exposure.

4. Insulation and sealing:

Silicone hose has good insulating and sealing properties, which can effectively isolate the current and the penetration of gases, liquids and other media. This makes 2740 silicone tube has important application value in electrical, electronic, medical, food and other fields.

5. Flexibility and elasticity:

Silicone tube has a high degree of flexibility and elasticity, can adapt to a variety of complex shapes and bending angles, while maintaining its original performance. This characteristic makes 2740 silicone hose in the need for frequent bending or deformation of the occasion outstanding performance.

6. Non-toxic and odorless:

The silicone material itself is non-toxic and odorless, and meets the relevant standards for food safety and medical devices. Therefore, 2740 silicone tubing will not be harmful to human health when used in food, medical and other fields.

Product Description and Application :

Acrylic coated fiberglass sleeve is E-glass fiber braided sleeving coated with a layer of acrylic resin.

It is a carefully engineered, high dielectric sleeving, having an initial average dielectric of 7 kV and a 1/32" wall outer layer of unsaturated glass, braided over and bonded to the acrylic sleeving.

It is a heat-treated, tightly braided fiberglass sleeving coated with a dielectric acrylic resin. This durable sleeving will withstand mechanical stress and holds it’s dielectric strength on all bends. It is extremely flexible and easily installed. It is used in electrical apparatus such as electric motors, transformers, generators, home appliances, lighting fixtures, instrument circuits and controls, switchgear, breaker panels, welding equipment.

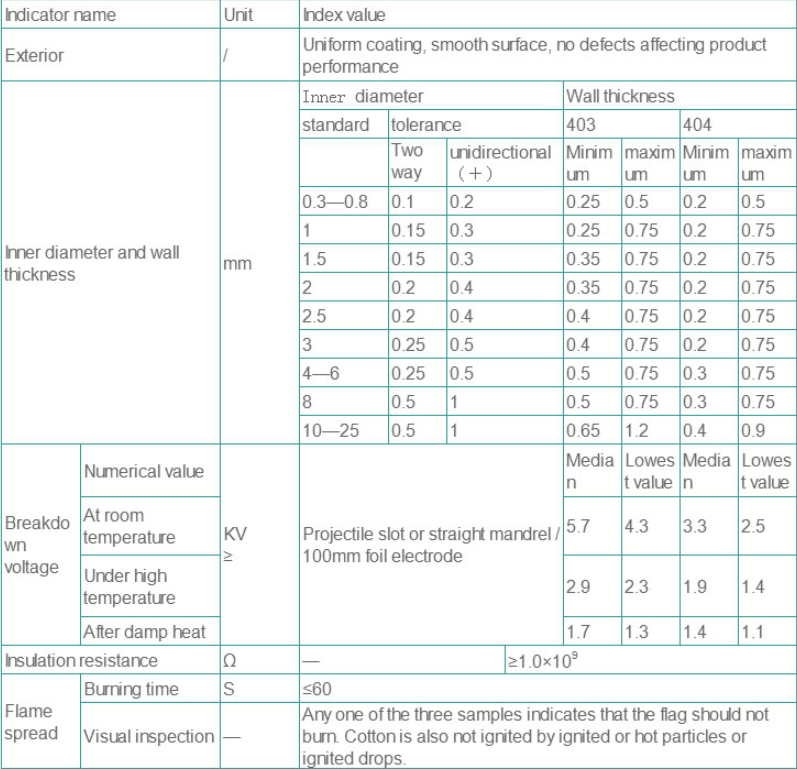

Technical Data sheet :

Motor usage scenarios:

FAQ:

Q1.Are you manufacturer or trading company ? Where and when founded?

A: We are facoory ,who is founded in 1997 and in Xuchang City,China .

Q2.What is the payment term of your company ?

A: Under normal circumstances, it is T/T. Large funds can also be 30% advance payment, and the balance is paid off before delivery.

Q3.What certificate do you have ?

A:ISO 9001 or other test report can be provided according to clients' require.

Q4.How do you make sure the quality?

A.We will consult on your requirement and recommend suitable products to you.We will send sample to you if possible. b.During production,we will always check quality ,package,delivery etc. c.Before package,with QA to check everything . d.After shipment ,we will consult you about satisfaction.

Q5.Can I get sample for free?

A: Yes,Sure,free samples ,customer pay shipping.

Q6.What's the shipping port?

A:Any port of China .

Q7.Can I visit your factory ?

A:Yes ,of course .We warmly welcome and entertain.

Q8. Do you accept customization?

A:Sure . We can customize according to customer needs, such as drawings.

Key words:

2740 Fiberglass sleevings coated with Acrylic resin

Get A Quote

Leave your contact information and get a free product quote

Solution

Since its establishment, Jingwei has always been committed to the field of electrical insulation materials. With excellent quality, innovative technology and professional services, it provides efficient and reliable insulation solutions to global customers, and has won the trust and praise of global customers.

Related Products

Since its establishment, Jingwei has always been committed to the field of electrical insulation materials. With excellent quality, innovative technology and professional services, it provides efficient and reliable insulation solutions to global customers, and has won the trust and praise of global customers.

6641 F-CLASS DMD Insulating composite paper

As a Class F insulating material (long-term operating temperature of 155°C), 6641 DMD excels in high-temperature environments. Its core layer uses a high-melting-point polyester film (e.g., 6020 electrical insulation polyester film), combined with Class F adhesive, which remains intact (no delamination or blistering) for 10 minutes at 180±2°C. This heat resistance makes it suitable for high-load motors, dry-type transformers, and other equipment, maintaining stable performance even during short-term overloads (e.g., 200°C).

Dupont Nomex410 insulating paper

Dupont Nomex410 insulating paper has excellent electrical properties, mechanical properties and thermal stability, suitable for a variety of electrical equipment.

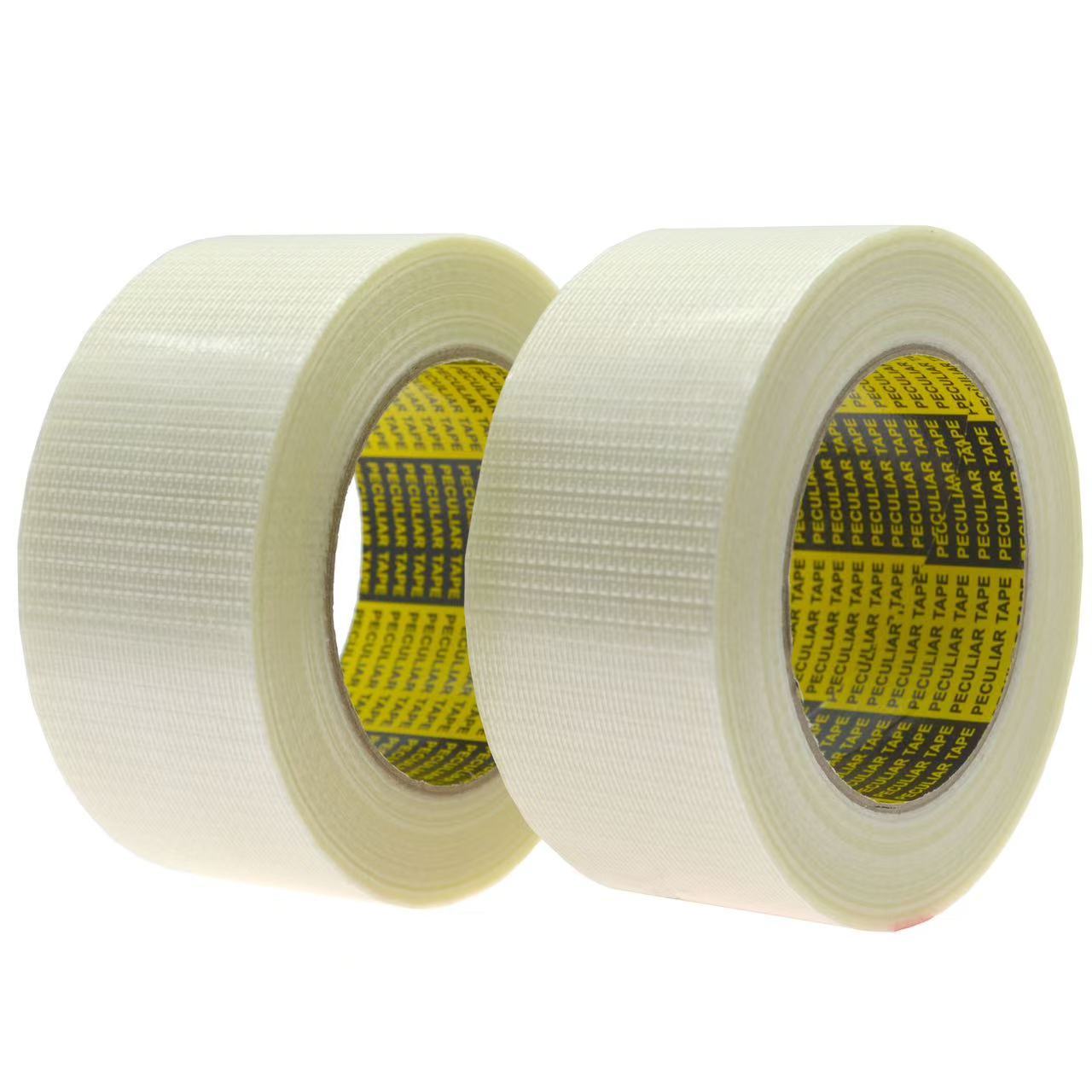

319K Parallel Fiberglass Tape (or Single Side Stripe Fiberglass Tape) is an adhesive tape product with a unique structure and excellent performance.

The products are mainly used for interlayer insulation of various transformers, motors, reactors, etc.