Top Tips for Using Mesh Fiberglass Tape Effectively: A Comprehensive Guide

Top Tips for Using Mesh Fiberglass Tape Effectively

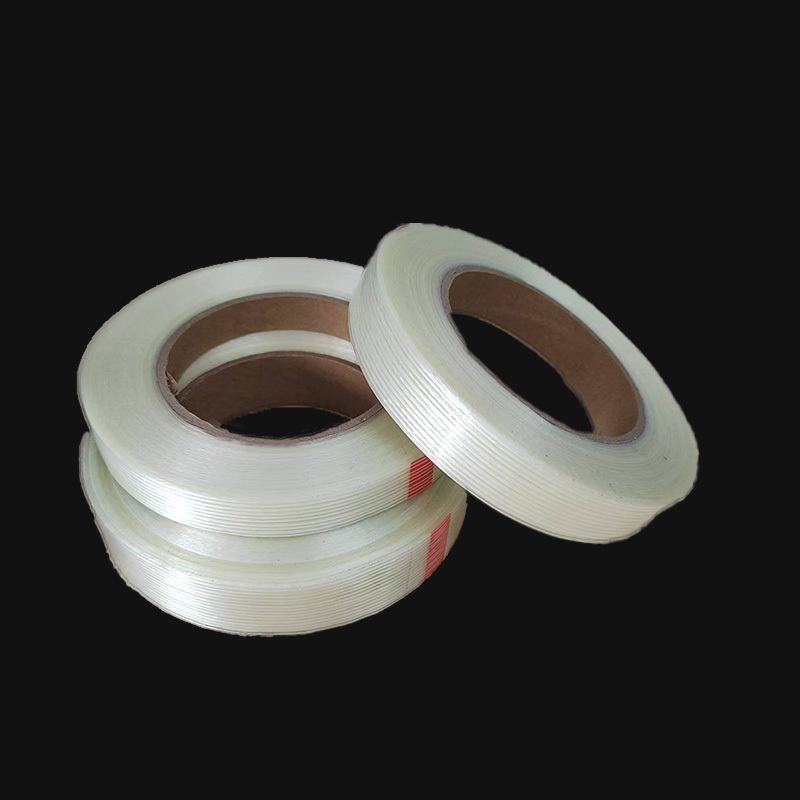

Introduction to Mesh Fiberglass Tape

Mesh fiberglass tape is an invaluable tool in the world of electrical work and construction. Its unique properties make it ideal for various applications, particularly in insulation and reinforcement. With its outstanding strength and adhesive characteristics, understanding how to use this tape effectively can significantly impact the success of your projects. This article presents top tips that will empower you to maximize the performance of mesh fiberglass tape, ensuring durability and reliability in your work.

Understanding the Composition and Benefits of Mesh Fiberglass Tape

Before diving into practical tips, it's essential to understand what mesh fiberglass tape is and why it's so beneficial. Made from woven fiberglass strands, this tape offers exceptional strength, flexibility, and resistance to environmental factors such as moisture and temperature fluctuations. The benefits of using mesh fiberglass tape include:

- High tensile strength: Perfect for reinforcing joints and seams.

- Moisture resistance: Ideal for areas prone to dampness.

- Ease of application: Can be easily cut and shaped as needed.

- Versatility: Suitable for various surfaces, including drywall, wood, and concrete.

How to Choose the Right Mesh Fiberglass Tape

Consider the Width and Thickness

When selecting mesh fiberglass tape, width and thickness are crucial factors. Depending on your project, you may need a wider tape for larger areas or a thinner one for detailed work. Generally, a width of 2 to 4 inches works well for most applications.

Evaluate the Adhesive Quality

The adhesive quality of the tape is paramount. Opt for tapes with high-performance adhesives that bond well to various surfaces. This ensures a secure application and minimizes the risk of peeling or lifting over time.

Assess Temperature Resistance

Depending on your work environment, you may need a tape with high-temperature resistance. Look for specifications indicating the tape's ability to withstand specific temperature ranges, particularly if you are working in extreme conditions.

Preparation: The Key to Successful Application

Clean the Surface Thoroughly

Before applying mesh fiberglass tape, always start with a clean surface. Remove any dust, dirt, or grease that may interfere with adhesion. A clean surface maximizes the bond strength and overall effectiveness of the tape.

Ensure Proper Drying Conditions

Moisture can compromise the adhesive properties of the tape. Ensure the area is dry before application. If working in a humid environment, consider using a dehumidifier or fans to improve drying conditions.

Application Techniques for Maximum Effectiveness

Cutting and Measuring with Precision

When using mesh fiberglass tape, precision is critical. Cut the tape to the required length using sharp scissors or a utility knife. Measure accurately to ensure a perfect fit around joints, seams, and corners.

Applying the Tape with Care

Start by placing one end of the tape on the prepared surface. Gradually press down while unrolling the tape to avoid air bubbles. Use a smoothing tool or your fingers to ensure a firm bond without wrinkles. Overlapping the tape slightly at seams enhances strength.

Layering Techniques for Enhanced Durability

For applications requiring extra reinforcement, consider layering the tape. Ensure that each layer is applied smoothly and without gaps. This technique can significantly increase the structural integrity of your work.

Finishing Touches: Ensuring a Professional Look

Applying Joint Compound or Plaster

After applying mesh fiberglass tape, it's essential to cover it with joint compound or plaster. This step not only improves aesthetics but also adds an additional layer of protection. Apply the compound smoothly over the tape, feathering the edges to blend with the surrounding surface.

Sanding and Smoothing the Surface

Once the joint compound is dry, sand the area lightly to achieve a smooth finish. Use fine-grit sandpaper for the best results. This step is crucial for ensuring the final appearance is professional and free of imperfections.

Maintenance Tips for Long-Lasting Results

Regular Inspections

After installation, it's advisable to perform regular inspections of areas where mesh fiberglass tape has been applied. Look for signs of wear, peeling, or damage. Early detection allows for prompt repairs, minimizing future issues.

Keeping the Area Dry

To maintain the integrity of your tape application, ensure that the area remains dry. Address any leaks or moisture issues promptly to prevent damage to the tape and underlying structures.

Common Mistakes to Avoid When Using Mesh Fiberglass Tape

Neglecting Surface Preparation

One of the most common mistakes is failing to prepare the surface adequately. Skipping this step can lead to poor adhesion and premature tape failure. Always prioritize cleaning and drying the surface.

Applying Tape in Damp Conditions

Applying mesh fiberglass tape in damp conditions can compromise its effectiveness. Ensure the environment is conducive for application to achieve the best results.

Frequently Asked Questions (FAQs)

1. What is mesh fiberglass tape typically used for?

Mesh fiberglass tape is commonly used to reinforce joints and seams in drywall, repair damaged surfaces, and provide insulation in electrical applications.

2. Can mesh fiberglass tape be painted over?

Yes, once the tape is covered with joint compound or plaster and dried, it can be painted over for a seamless appearance.

3. How do I remove mesh fiberglass tape?

To remove mesh fiberglass tape, carefully peel it off the surface. If it resists, use a heat source like a hairdryer to soften the adhesive before removal.

4. Is mesh fiberglass tape waterproof?

While mesh fiberglass tape is moisture-resistant, it is not entirely waterproof. It is advisable to use it in dry or well-ventilated areas.

5. How long does mesh fiberglass tape last?

With proper application and maintenance, mesh fiberglass tape can last for many years, providing ongoing strength and support in your projects.

Conclusion

Utilizing mesh fiberglass tape effectively requires knowledge, precision, and attention to detail. By understanding its composition, choosing the right type, and following best practices in application and maintenance, we can ensure that our projects achieve the desired strength and durability. Avoiding common mistakes and regularly inspecting the tape will contribute to long-lasting results. With these tips, you’ll be well-equipped to leverage the full potential of mesh fiberglass tape in your electrical or construction endeavors.